Agronomy Update

Aug 11, 2025

Fall Weed Control: A Strategic Step for Spring Success

While we still have to get much of the 2025 crop in the bin, it is not too early to start thinking ahead to next season. Many weeds are making harvest a challenge this year and you can take note of the weeds present in your maturing fields to anticipate problems for next year. Applying a fall burn down and/or residual gives you access to a different suite of products and this timing also allows you to get additional control on hard to manage perennial and winter annual weed species. When we have dry conditions at planting, spring applied residuals can be less effective. By doing a fall burn down and applying a residual, we reduce the number of weeds going to seed and provide residual control for early emerging weeds in the spring.Fall weed control can help manage two weeds that have been prevalent this year, kochia and marestail (aka horseweed).

Horseweed seedling (rosette) and mature plant. Photo credit: S.L. Meyers and P. Merritt

Horseweed is a winter annual that can emerge in both fall and spring, so getting a head start on managing it in the fall can provide very effective control for the next season. Up to 91% of the fall emerging horseweed plants will survive to the spring and this weed is much easier to control in the rosette stage vs the bolting stage. Kochia seedlings, being very cold hardy, are among the first to emerge in the spring, sometimes well before it is warm enough to spray, and this is where a fall applied residual can provide control.

Before selecting your fall weed control program, field scouting is critical. Check your fields 1–2 weeks after harvest to assess post- harvest weed pressure and weed species. Depending on your weed spectrum you may be looking at an application shortly after harvest, and/or a fall residual application after soil temperatures drop. With the rainfall we’ve seen this month, don’t be surprised if fall weed pressure is higher than usual.

Reach out to your local Horizon Resources agronomist if you need help with scouting.

Weed Control in the Age of Herbicide Resistance

Herbicide resistance has complicated the use of fall residuals for kochia. In addition to widespread group 2 and glyphosate resistance, now group 14 resistant kochia has been added to the mix. This is a good use case scenario for Anthem Flex, which contains a group 15 active ingredient (pyroxasulfone: zidua) that provides residual suppression of kochia and control of several grass species and other broadleaf weeds, along with the group 14 herbicide contained in Aim (carfentrazone) for burn down activity. Anthem Flex requires sufficient moisture to be activated and thus a fall application is recommended in our growing region. Valor (flumioxazin) is still a very effective product for susceptible kochia and winter annuals like horseweed. Using a combination of these products in your fall residual herbicide program may slow the spread of resistance and improve kochia control. Fierce EZ is a pre-mix of pyroxasulfone and Valor that would be an option in some crops.Rotation and Resistance Monitoring

Keep in mind crop rotation restrictions for all products applied in the fall. For example, Valor at a 2 oz./ac rate, has a 6-month plant backinterval to lentils. Anthem Flex cannot be applied prior to durum. Page 6 of the 2025 NDSU Weed Guide has a table with rotation restrictions. The importance of rotating herbicide modes of action within your crop rotation cannot be stressed enough. With growing resistance in tough weeds like kochia and horseweed, rotating chemistries, along with using sufficient water volumes and effective adjuvants, helps preserve herbicide effectiveness.

As mentioned in the last issue of this newsletter, the National Agricultural Genotyping Center in Fargo, ND, offers herbicide resistance testing for Kochia—an excellent resource that is currently available for free to any North Dakota resident. Testing gives you the opportunity to proactively manage herbicide resistance instead of bat- tling a large resistant population.

Conclusion: Set the Stage Now for a Cleaner Spring

While no solution is perfect, and we will inevitably battle weeds in the spring, a well-executed fall herbicide program can set you up for a cleaner start and give your crop a better shot at early-season success. Long term, fall weed management can get challenging perennial weeds under control and help battle the growing problem of herbicide resistance.Lucas Holmes, MS

Agronomist, Zahl Location

Fairview Agronomy Update

Soybeans

Most of the soybeans in the valley are in R4-R5 stage and still stand- ing upright. There has been high risk of white mold, with the weather being wet and rainy. We are still on the lookout for soybeans that may be affected by this disease. Some of the fields that were sprayed with fungicide last week show the effects of plant protection and are the tallest soybeans in the valley with excellent pod potential.

Dry Beans

The pinto beans are well into pod fill and have had some instances of bacterial blight recently. A product called OxiDate 5.0 was used on some pintos to reduce the damage of the bacterial blight in the field. It has been a week since that application, and the new tissue appears healthy.

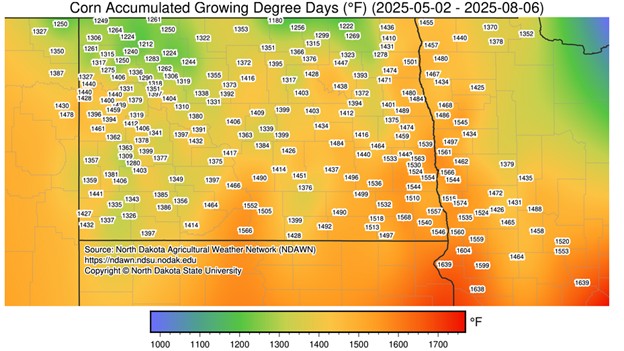

Corn

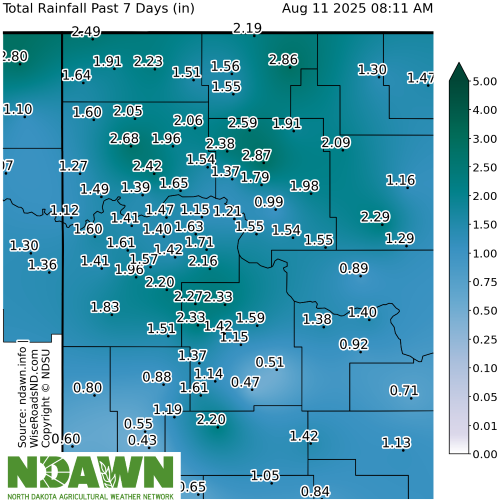

The amount of precipitation has helped with the corn crop this year. But we still have many GDD units until the corn has reached maturity. The map shown below is a representation of the accumulated GDD from May 1st until August 6th.

With a target of 2,400-2,800 GDD we still have months to go until the crop reaches maturity. It’s a good reminder to consider the water needs of corn and don’t quit irrigation too soon in September, it needs water up until black layer stage (R6).

Corn Plot Demo

We will be having a test plot demonstration just north of Fairview, MT on September 5th in the afternoon on a plot that was planted with several corn varieties from different seed companies, more details to follow.Julia Seiller

Agronomist, Fairview Location

Zach Weiland

Agronomist/Future Manager, Fairview Location

Desiccation and Pre-Harvest Weed Control

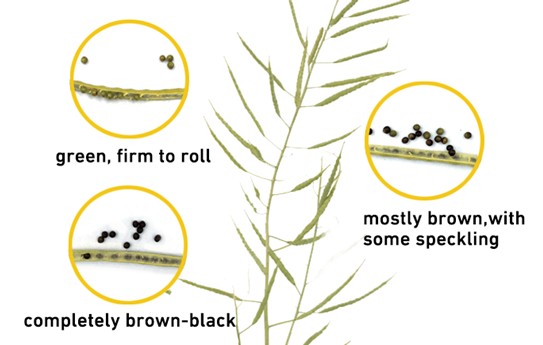

While we always have to be grateful for rain, it certainly has brought some challenges this harvest season. In lentils, staging the crop for desiccation timing is going to be an issue this year between the green regrowth and weed pressure. In some durum and wheat fields, weeds are growing so quickly that they may cause harvestability issues as they reach crop height and higher. In the case of canola, uneven maturity means growers will have to weigh their options for harvest timing. With the time it might take to kill weeds and dry the crop down, these fields will need to be monitored closely for timely desiccation and pre-harvest weed control decisions.As we have been out scouting lentil fields, it has been common for us to observe completely green plants that have mature pods most of the way up the canopy. There have also been areas where the crop appears green from a distance but when you get in the field all but green regrowth at the top is ripe.

The appropriate stage for desiccation is when the bottom third of the pods are brown and rattle when shaken. Seeds from the middle third have changed from green to tan-brown and pods in the top third have 50-75% color change with no immature seeds.

Lentil pods and seeds at desiccation stage (30% moisture). Source: Saskatchewan Pulse Growers

Fields will not uniformly mature, but when the majority of the field reaches this stage it is ready for desiccation. While spraying too early does risk downgrading, spraying too late risks yield loss due to shatter. Don’t risk the majority of your field waiting for everything to mature.

Pre-harvest weed control in durum will be a challenge. There is just no good solution for 3 foot tall kochia when paraquat isn’t an option. Below are the options for pre-harvest weed control for durum and spring wheat.

· Glyphosate (7 day PHI)

· 2,4-D (14 day PHI)

· Dicamba + 2,4-D (7 day PHI)

· Sharpen (3 day PHI)

· Valor (10 day PHI)

Application timing is when the crop is at the hard dough stage with 30% or less moisture (middle picture below).

From left to right: late milk, soft dough, hard dough, hard kernel, harvest ripe. Source: BBCH Staging Manual, OSU.

Despite a shorter PHI, it is very unlikely that large weeds sprayed with Sharpen will be dead after 3 days. Expect that you will be waiting closer to 10 days before harvesting. Grain buyers may also want to see a PHI of 10 days regardless of the product used.

Make sure to keep the water volume at 15 to 20 GPA to get adequate coverage and include AMS and MSO. Even doing the best job possible, it is unlikely you are going to kill huge kochia so keep your expectations low. You will not be able to save seed from fields sprayed with glyphosate or Sharpen. If you plan to bale straw, check the label for restrictions before application.

Low plant population, uneven emergence, water ponding, insect damage, crop residue, and hail can all lead to an uneven canola crop. Growers who might be considering desiccation to facilitate harvest should assess where most of the yield will come from, and make a decision based on when those seeds mature. Green pods can still contain mature seed so check pods to see if the seeds are firm and have started to change color. Depending on the situation, it could just be a better choice to delay harvest to even up the field or cut it before the earlier crop will interfere with combining and air dry the grain. If neither of these scenarios fit your situation then desiccation may be a viable option.

Glyphosate, Sharpen and Reglone can be used in canola pre-harvest. All of these products have their downsides so this will probably be a field by field decision. Reglone kills quickly, but immature seed will be locked in once you spray and this could lead to unacceptably high green count. Application timing is when 90% of each plant has seeds that are completely brown. You should not see any yellow or green across the field. This is likely not the best choice in fields with extreme variability in maturity where green pods and seeds are present. If you apply Reglone and then get rained out when the crop is ready to harvest, it could significantly increase risk of pod shatter and pod drop.

Sharpen can be applied once 80% of the crop has brown seed. In cool and rainy conditions though this product may not sufficiently speed harvest. The crop can be ready anywhere from 7 to 21 days post application and could be longer. Sharpen is frequently tank mixed with glyphosate for pre-harvest weed control.

Glyphosate has the earliest application timing out of these three products and can be applied when seed from the least mature plants reaches 30% moisture (picture below). This corresponds to roughly 50-60% seed color change in the least mature areas of the field. Because the rate of dry-down after glyphosate application can be so long, it will frequently not speed crop maturity.

Unfortunately it seems like our current weather pattern is going to create a lot of challenges this harvest season. Feel free to reach out about options and if you’d like us to go out and look we are happy to help.

Dr. Audrey Kalil

Agronomist/Outreach Coordinator

Heavy rains, regrowth, and delayed desiccation. This episode of “On the Horizon” dives into the unexpected agronomic conditions shaping this year's harvest. Audrey and Levi break down late-season issues impacting lentils, durum, and canola, including pod integrity, green count concerns, and fungicide timing. Listen here or on your podcast app and don’t forget to subscribe!

Submit Maps for Soil Sampling

We will get started on soil sampling soon and will be offering both conventional and zone sampling again this year. When dropping off maps, please include the 2025 crop and possible crops for next season.We don’t know what kind of weather the fall will bring so don’t wait until October to drop off your maps. The sooner we have them, the sooner they will be done!

Sara Erickson

Agronomist, Williston Location

Soil Sampling Pays – Make Every Acre Count

Harvest season is rolling along, and while your focus is rightfully on getting this year’s crop in the bin, it’s also the perfect time to look ahead. Planning for next year’s success starts now and one of the smartest moves you can make is booking your soil sampling.

Right now, we’re at an intersection between low commodity prices and high fertilizer costs, a combination that makes precision in your nutrient program more important than ever. Guesswork simply isn’t an option. Every pound of fertilizer needs to be placed where it will have the greatest return, and the only way to know that is by testing your soils.

Soil sampling consistently ranks as one of the highest return on investments in farming. The cost is minimal compared to the value of the information it provides. These tests aren’t just for deciding next year’s fertilizer rates, they’re a diagnostic tool for your fields. They can explain why yields vary from field to field or even from one part of a field to another.

Maybe you’ve got one quarter that consistently underperforms, even though the soil type looks similar on the surface. Without soil test data, you’re left guessing. With it, you might uncover a nutrient deficiency, a pH imbalance, or other issues cutting into your bottom line. Once you know the problem you can fix it or at least manage it more profitably.

Horizon Resources offers two levels of soil sampling to fit your needs:

- Composite sampling - for a broad overview of your nutrient status.

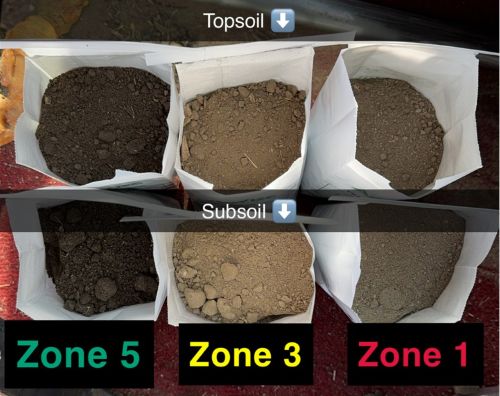

- Zone sampling - custom-tailored to each field’s productivity zones.

By sampling each zone separately, you can set realistic yield goals for each one. The lower-potential zones may get less fertilizer, while the high-potential areas get more, feeding them to their full capacity. In many cases, this isn’t about applying more fertilizer overall, it’s about reallocating your resources to the spots that will give you the greatest return. The result is more consistent yields, better grain quality, and the most efficient use of every fertilizer dollar you spend.

The concept is simple: farming without soil sampling is like driving without a fuel gauge. You wouldn’t head out on a long road trip without knowing how much gas is in the tank. Will you make it to the next station, or will you stall out on the side of the road? In the same way, planting without knowing your soil nutrient levels is a gamble, one that can cost you yield.

Every field is different. Every crop has unique nutrient needs. This fall, as you wrap up harvest, don’t leave next year’s success to chance. Today, our soil sampling with Horizon Resources today, whether standard composite or precision zone sampling and put the right nutri- ents in the right place for the right return.

Kyle Okke, CCA Agile Agronomy LLC

Agronomists Happy Hour Podcast

Scouting for Head Scab

The pathogen associated with head scab is always going to be present at some level in our growing region due to extensive wheat and durum production. Disease development is therefore primarily driven by the weather. With the consistent rainfall over the past three weeks we have had high risk levels for head scab since roughly mid-July. While this puts our later planted acres at the highest risk, there are implications for the earlier planted crop as well.Anthers extruded during flowering are the primary infection site for the head scab pathogen. That is why we typically apply a fungicide at that stage. If anthers are infected just after emergence the pathogen will kill the floret so that the grain does not develop and thus yield loss, and not VOM, will be the primary symptom.

Florets infected just after that point produce the shriveled, white “tombstone” kernels which contain significant levels of VOM. Wheat heads are still susceptible to colonization by the pathogen until hard dough, and these kernels may appear healthy but still contain VOM. The head scab pathogen spreads within infected wheat or durum heads under humid and wet conditions. This is why disease development has likely occurred over the past few weeks.

Symptoms of head scab are typically assessed at the soft dough stage and scouting can continue as the healthy heads remain green. Monitor fields up until they begin to mature, as you can sometimes see a big difference in symptoms in just a weeks time. Partially bleached heads are the characteristic symptom of head scab, and you can dissect heads to assess the grain as well. Fungal growth that is pink to salmon colored may be present when humidity is high.

Head scab symptoms in McKenzie County on August 4th, 2025.

Salmon colored pathogen growth on wheat head (left). Scabby grain (right). Photo Credit: Crop Protection Network.

A few infected heads in the field doesn’t necessarily mean you will have VOM in the grain at detectable levels, but if you see a lot of heads infected and a greater proportion of the heads are diseased (ex. one spike vs half to full heads) that might be a field you want to segregate from the healthier crop. Cleaning out the tombstone kernels or using scabby grain as seed are both options for dealing with VOM contaminated crop. Scabby seed will have lower germination and have the potential to develop seedling blight, so that seed should be tested and fungicide treated to manage that risk.

Dr. Audrey Kalil

Agronomist/Outreach Coordinator