Agronomy Update

Oct 07, 2025

On the Horizon Podcast Season 2, Episode 38: Fertilizer Markets, Buying Power, and Cooperative Advantage

In this episode of On the Horizon, Levi sits down with Jon Berglund of Prairie Land Ag, a cooperative buying group serving independent ag retailers across the Midwest. Jon shares Prairie Land’s story, its $1.4 billion footprint, and how their collective buying power helps members compete with national players. The conversation dives into today’s fertilizer markets, why prices are elevated, the global factors driving supply challenges, and where farmers can find glimmers of hope heading into next season. Listen on Spotify, YouTube or wherever you get your podcasts.

Changes to State Pesticide Law and Pesticide Certification Renewal Trainings for 2025/2026

The EPA and the North Dakota Pesticide Act requires an individual to become certified if they are using or merchandising a Restricted-Use- Pesticide (RUP). Examples include Gramoxone/Helmquat, Tordon, Lambda Cy and Huskie Complete. As of August 1, 2001, North Dakota also requires commercial and public applicators to become certified to use general-use pesticides. Private applicators do not need to be certified to use general use pesticides. Most farmers fall into the private applicator category unless they apply commercially off farm.Formerly, private applicators who were not certified could apply RUPs if they were supervised by a certified applicator. Supervision is defined as being accessible by phone and within 30 minutes of the non- certified applicator. State law modified that requirement in 2025 such that only certified applicators can apply restricted use fungicides and insecticides. Non-certified applicators can still apply restricted use herbicides if they are under the supervision of a certified applicator.

The first Ag Pest training offered virtually is on November 13th, 2025 from 9 am to 4 pm CST and the next virtual training is March 17th, 2026. The Williston in person training is March 26th, 2026.

All trainings require pre-registration. See the attachment or the NDSU pesticide certification website for more information.

2025 Fall Valor® Application FAQs

I hope this fall season finds everyone doing well. As we wrap up the 2025 harvest and growing season, now is a great time to start preparing our fields for next year.In my area, I see a wide range of fall practices—from tillage and residue management to fertilizer applications and fall herbicide programs. With that in mind, I want to take a moment to address some frequently asked questions about applying Valor® in the fall for residual broadleaf weed control going into the spring of 2026. Below are some answers to frequently asked questions.

What is the plant back interval for fields going to lentils?

- 2 oz is 6 months

- 3 oz is 7 months

- 4 oz is 12 months in no-till, and 6 months if the soil is tilled. Plan accordingly to reduce injury.

What is the plant back interval for fields going to durum?

- Fall Valor is safe to apply prior to spring planted durum

- 3 oz is 2 months with 1 inch of rainfall

- 4 oz is 4 months

What weeds does Valor provide residual control of when applied in the fall?

- Mustard species (wild mustard, tansy mustard etc.)

- Marestail

- Narrowleaf hawksbeard

- Common lambsquarters

- Henbit

- Chickweed

- Dandelions

- Nightshades

- PPO susceptible kochia

Should I tank mix Valor in a Fall application?

It’s important to get a good kill on existing weeds and let Valor prevent new weeds from growing. For that reason, I recommend a broadleaf and grass herbicide (e.g. glyphosate) in the tank with Valor.

What other Fall residual options are there?

For fields going into corn, spring wheat, sunflowers, or soybeans, I recommend using one of the Fierce® brands. These pre-mix products contain Valor® (flumioxazin), pyroxasulfone, and metribuzin, and have been shown to be effective against PPO-resistant kochia.

The addition of pyroxasulfone and metribuzin helps extend the residual activity of Valor when applied in the fall, providing longer- lasting weed control into the spring and additional grass control.

Valent offers two Fierce products suitable for our region:

- Fierce EZ – does not contain metribuzin

- Fierce MTZ – includes metribuzin

My personal preference for fall applications is Fierce EZ, as I like to reserve metribuzin for spring use where possible. While metribuzin is very effective in fall, it is more water-soluble than Valor. In seasons with above-average fall precipitation and warm temperatures, metribuzin effectiveness can diminish due to leaching or breakdown.

How well does Valor work with heavy crop residue?

Valor does not bind to residue making it perfect for no-till and higher residue situations. With a little moisture as snow or rain the Valor will make soil contact. Use at least 20 GPA to help increase efficacy in those fields with heavier crop residue. 15 GPA can be used for all other applications.

When can I start applying Valor this fall?

The easy quick answer is when soil temps are below 50 degrees. Keep in mind if you plan to do any tillage or residue management, do so prior to applying Valor. Applying fall Valor should be the last step in growing season 2025.

Have a great Fall!

Mike Ryckman

Valent Territory Account Manager North Dakota/ Northeast Montana

Planning for Next Year’s Lentils Starts Now

With lentils still looking strong from a profitability standpoint, many growers are considering expanding acres. Before doing so, it’s worth taking a closer look at what was applied to those fields this season, because carryover herbicides can make or break next year’s success.What Was Applied to the Current Crop?

In most rotations, lentils follow wheat, durum, or sometimes corn. That means it’s important to review what herbicides were used on those crops and understand their rotation restrictions.

Wheat/Durum

Products with Clopyralid (Group 4)- Examples are Stinger, Widematch, PerfectMatch, Weld, and generics

- Rotation Restriction: 18 months

Group 27 Products

- Examples are Huskie, Huskie Complete, Huskie FX, Talinor

- Rotation Restriction: 18 months

Products with Halauxifen (Elevore family)

- Elevore, Qulex, Rezuvant

- Rotation Restriction: 15 months

Products with Flucarbazone (Everest 3.0 family)

- Everest 3.0, Irongate

- Rotation Restriction: 18–24 months (depending on soil pH)

Corn

Group 27 Corn Herbicides

- Examples include Armazon/Pro, Callisto, Laudis, Diflexx Duo

- Rotation Restriction: 18 months

Products with Clopyralid

- Stinger, Widematch/Generics, SureStart, TripleFlex

- Rotation Restriction: 18 months

Atrazine

- 12 oz or less: Next cropping season is ok

- More than 12 oz: Two cropping seasons cool off is needed

Note: This is not a complete list, but it covers many commonly used products. Always review product labels or consult your agronomist before penciling lentils into next year’s rotation.

Post-Harvest or Fall Burndown Considerations

It’s common to see dicamba and 2,4-D used in fall burndown applications, but lentils are highly sensitive to dicamba residue. Labels often provide limited rotation information, so timing becomes critical:

- Dicamba: Safe for lentils only when applied through August and early September. Avoid applications after mid-September.

- 2,4-D: Lentils show low sensitivity; safe to use even later into fall.

If your goal is late-fall thistle control, skip dicamba and rely on 2,4-D plus a high-rate of glyphosate instead. This combination will target perennial weeds moving energy into their roots without risking next year’s lentil stand.

Late-Fall Residual Herbicide Options

Once soil temperatures average 50°F or less for about a week, microbial activity slows down, and it becomes “go time” for residual herbicide applications. These products persist through winter to control early spring flushes of kochia, hawksbeard, pigweed, and grasses before in-season spraying is possible.

Key Residual Options:

| Active Ingredient | Example Products | Lentil Rotation Restriction | Notes |

| Flumioxazin |

Valor, Panther, generics | ≤2 oz = 6 months; up to 3 oz = 7 months | Strong on hawksbeard and kochia |

| Pyroxasulfone |

Zidua, Anthem Flex |

≤7.5 oz = no restriction |

Best on grasses and small- seeded broad- leaves |

| Combination |

Fierce |

≤6 oz = 6 months | Broad-spectrum; strong on kochia and grasses |

From experience, Fierce has been the most consistent on kochia in lentil rotations, combining the strengths of both flumioxazin and pyroxasulfone.

Bringing It All Together

What you applied over the last two seasons plays a major role in determining if lentils fit into your 2026 plan. Take inventory now, know what’s been sprayed and where. Tools like FarmQA and services offered through Horizon Resources can make that tracking process easy and reliable.Once you’ve confirmed rotation compatibility, plan a late-fall residual that fits your weed spectrum and field conditions. A little planning now ensures that when seeding season arrives, your lentil acres will start clean and stay competitive.

Kyle Okke, CCA

Agile Agronomy LLC, Agronomists Happy Hour Podcast

Plan Ahead to Manage Root Rot in Peas and Lentils

Aphanomyces root rot has taken some farmers out of the pulse business completely in Northwest ND and has caused significant yield loss in areas of Northeast Montana as well. While we did not have reports of significant yield loss to root rot this year, Aphanomyces was present in the roots of plants in 10 out of the 20 pea and lentil fields I surveyed in 2025 for root disease.This pathogen is native to our soils, and every time we grow peas or lentils, we grow the pathogen as well. By producing thick-walled spores called “oospores,” Aphanomyces can survive for 10 years or more making preventative management key. When selecting fields for pea or lentil cultivation in 2026 assess your root rot risk to help ensure successful pulse production in the decades to come.

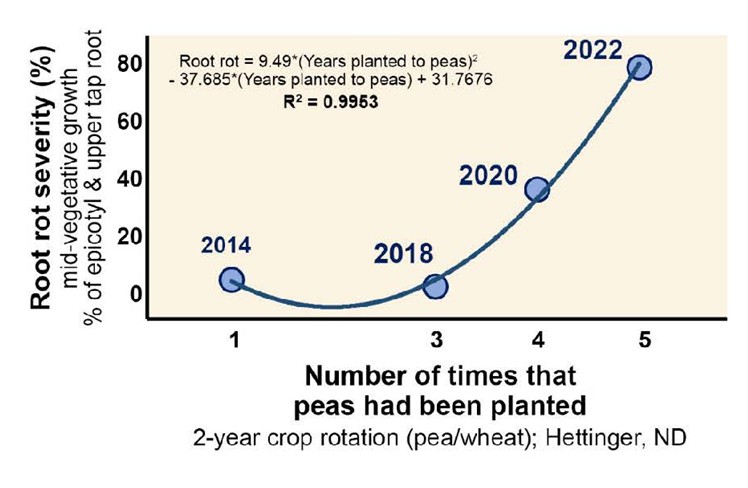

Crop Rotation

A crop rotation study was initiated at the NDSU Hettinger Research Extension Center by Agronomist John Rickertson in collaboration with Plant Pathologist Dr. Michael Wunsch, to understand how root rot develops in a field with no previous history of pulse production. As one might expect, root rot severity increased with the number of times that field was planted to peas (graph below). By the 5th time peas were planted in a two year rotation, root rot severity went from 2% to 79%. This had not yet resulted in a corresponding yield loss, likely due to dry conditions in that year. However, these high levels of disease mean a corresponding increase in the amount of pathogen in the soil. That is what sets the stage for yield loss if peas or lentils are planted in that field when conditions are conducive for disease.

Given that pea and lentil production has been widespread in our region for many years, it is likely that most fields have some level of root rot pathogens present. However, fields with short rotations (2-3 years) will have highest pathogen levels and these fields would benefit from a long rotation away from these crops. Crop rotation studies conducted at the NDSU Carrington REC by Dr. Wunsch has found that a six year rotation is required to reduce root rot disease and increase yield compared to a two year rotation.

In 2018 and 2022, root rot severity was similar between the two-year rotation (pea/wheat) and the four-year rotations. While yield was higher in the four-year rotations, these yields are still considered low in the Carrington area, particularly in 2022 where yields were 17-25 bu/A in the four-year rotations. In 2020, they compared two-, three- and six-year rotations of pea and wheat, along with barley, canola and corn in the six year rotation. The six-year rotation had less disease and higher yield than the two and three year rotations.

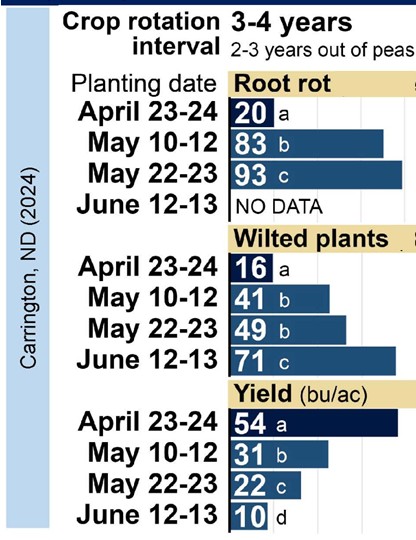

Planting Date

While long rotations are an important management tool, if you are unable to stretch your rotation beyond the 3-4 year timeframe there are still things you can do to mitigate yield loss due to disease. By planting early when soil temperatures are around 45°F degrees at a two inch depth averaged across the week after planting, you still might be able to achieve acceptable yields in the presence of root rot pathogens. That is because Aphanomyces likes warm soils, and by planting in cool soils you give your crop a head start. Planting in late April rather than mid to late May has a significant impact on the level of root rot, wilt and ultimately yield (graph below, courtesy Dr. Wunsch).

Keep in mind that planting early limits your ability to kill weeds in your spring burndown, and we have no good options for broadleaf weeds in crop. If you are planning to plant lentils or peas early to mitigate root rot in a field with a long history of frequent pulse crop production, then your fall burndown and residual herbicide program is especially important. If that field had a bad kochia problem this year then it might not be the best choice for lentils next year.

Early planting also puts you at greater risk for seed rot and seedling blight diseases, and should be combined with the use of a fungicide seed treatment.

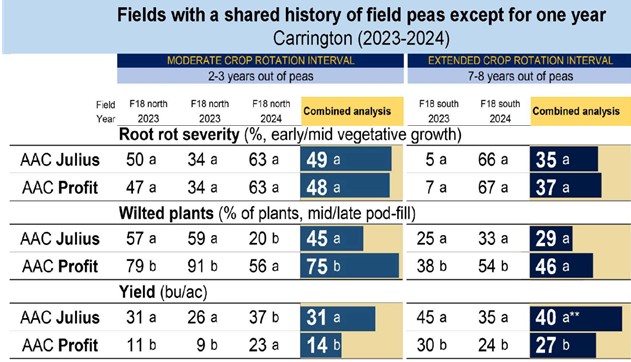

Variety Selection

Recent research has identified AAC Julius as a variety with tolerance to Aphanomyces root rot. Until now, previous studies had shown that the pea and lentil varieties grown in our region were all similarly susceptible to root rot. In the graph below, Dr. Wunsch highlights the impact of both variety selection and crop rotation length. By extending the rotation length and planting AAC Julius, yield increased from 14 bu/AC (AAC Profit in a 3-4 year rotation) to 40 bu/A (AAC Julius in 8-9 year rotation). Breeding programs have been actively working to incorporate resistance into new varieties, so I am hopeful that we will have more Aphanomyces tolerant options available in the future.

Early Detection

Managing root rot requires the combination of long term planning, investment in improved genetics and the use of fungicide seed treatments. If you are unsure whether root rot is an issue in your fields, use the new testing service from the National Ag Genotyping Center and get your soil tested. If you have questions about how to submit a sample or interpret your results please reach out. Root rot can be devastating when it takes hold in a field, but with the tools and knowledge available today, we have a much better chance of staying ahead of the problem.

Dr. Audrey Kalil

Agronomist & Outreach Coordinator

New CROPLAN® Canola Varieties for 2026

There are two new shatter tolerant products available from CROPLAN for 2026: CP7500LL LibertyLink® and CP9551TF Truflex.CP7500LL is a mid-maturity variety with high yield potential. The main benefit of this new release is its improved shatter tolerance over the rest of the CROPLAN LibertyLink lineup. It is a medium tall variety, with a strong disease package including blackleg resistance, resistance to multiple clubroot pathotypes and tolerance to verticillium stripe. It has higher oil and lodging tolerance scores compared to CP7130LL and CP7250LL.

CP9551TF also brings improved shatter tolerance to the CROPLAN Truflex line-up along with great standability and high yield potential. This is a 90-day variety, falling right in the middle of the 88-day CP9221TF and the 92 day CP9978TF.

Curt Droogsma, CCA Sales Development Manager

Winfield United

Buy Now for 2026 Grain Bins

We are getting close to the end of our grain in build season, and this was a pretty successful year for grain bin sales for Horizon Resources. We had two of our employees with the H2A program last year building grain bins with a third party builder and they, along with three other H2A employees, became our grain bin crew this summer. I can’t tell you how nice it is to have our own grain bin crew again and how nice it is to have a crew that will work as long as it takes to get our grain bins finished. The only thing I ask of them is to keep everyone safe, and to not lift bins with jacks when the wind is blowing excessively, which can be extremely dangerous. These guys usually show up at the bin sites, which are as far away from Williston as about 75 miles this year, at around 7:00 am and they are usually at the bin site working until at least 6:00 pm.We will have put up 16 bins this summer and they are all flat bottom bins with full floor aeration systems that include unload systems, fans and spiral staircases. These are top quality bins and most of the bins that we sold this year are 36 ft diameter 25,000-bushel grain bins. We match the fans to the bin sizes, and we spec them out for natural air drying without adding additional heat. We do have access to low temperature heaters for our bin systems, but our harvest weather is normally hot and dry, so we don’t typically need extra heat. We have also sold temperature and moisture cable systems that can be as simple as a couple cables in a bin using a handheld monitor or smartphone to read the temperature and moisture, up to complete systems with several cables per bin along with weather stations, fan controls and programs that you can run from your computer or smartphone.

Grain bins, just like everything else in farming keep getting bigger and farmers keep growing more bushels, so our grain bins have evolved from 3,000-bushel bins up to 30,000 bushels. That has probably been the biggest driver of our grain bin business over the years as growers just wanted to quit using those smaller bins and have kept building larger bins starting at 10,000 bushels, up to 35,000 bushels.

Some people don’t realize that we sell grain bins since you don’t really see grain bin materials here until we unload semi loads into our warehouse, but we have sold a substantial amount of grain bins throughout my career. I keep pretty good records, so I can tell you that we have now sold a total of 577 grain bins, that will store 7,684,383 bushels, with total sales of over $14 million in grain bins. This year alone, we have sold about 370,000 bushels worth of storage with just 16 grain bins.

Now is the time to buy!! We are currently getting our early winter pricing, which is usually the best time to buy grain bins. Our building time is July through October, and during that time we can normally build about 15 bins. Stop by and get your name on our build list for 2026!

John Salvevold, CCA

Agronomy Division Manager

Weather and Soil Temperature Update