Agronomy Update

Jun 02, 2025

Grass Herbicide Options in Wheat

As we roll into the busy season of in-crop herbicide applications for small grains, many of us are facing significant grass pressure. Choosing the right herbicide is critical for achieving season-long control, and with limited post-emergent options, selecting and rotating chemistries strategically is more important than ever.Currently, we have only a few modes of action available for post- emergent grass control:

- Group 1 – ACCase Inhibitors

- Group 2 – ALS Inhibitors

- Group 27 – HPPD Inhibitors (NEW for 2025—no wild oat control)

Even within a single mode of action, not all herbicides are the same. For example, Group 1 herbicides are subdivided into three chemical families: FOPs, DIMs, DENs. Each acts slightly differently, and resistance to one doesn’t always mean resistance to all. Studies have shown that foxtail or wild oat populations resistant to FOPs may still be susceptible to DIMs or DENs. Thoughtfully rotating between these families can help preserve efficacy and extend the life of these tools.

Examples of Group 1 Herbicides:

FOPs

- Fenoxaprop – Puma, Tacoma, Parity

- Clodinafop – Discover NG

- Quizalofop – Assure II (not labeled for use in small grains)

DENs

- Pinoxaden – Axial XL

DIMs

- Clethodim – Select, Section (not labeled for use in small grains)

Group 2 herbicides are also divided into several chemical families, including: Imidazolinones (IMIs), Sulfonylureas (SUs) and Triazolopyrimidines (TPSs) and Triazolinones. Similar to Group 1, rotating among these families can help manage resistance. Some grass populations may be resistant to one family but not others—even within the same group.

Examples of Group 2 Herbicides:

IMIs

- Imazamox – Beyond Xtra (for Clearfield-tolerant varieties only)

SUs

- Metsulfuron – Ally

- Tribenuron – Express

- Thifensulfuron—Harmony

- Mesosulfuron – part of Rimfire Max

TPSs

- Pyroxsulam – OpenSky, PerfectMatch

Triazolinones

- Flucarbazone – Everest 3.0

- Thiencarbazone – Varro

New in 2025: Group 27 HPPD Inhibitors

The latest addition to our weed control arsenal is the Group 27 HPPD inhibitors, sometimes referred to as “bleachers” due to the whitening effect they have on weed growth points. The only active ingredient in this group available for small grains is topyralate, marketed under two product options:

- Tolvera (topyralate + bromoxynil)

- Shieldex (standalone topyralate)

Also worth noting is the synergistic effect between topyralate and bromoxynil on broadleaf weeds. Tolvera often provides better tank-mix flexibility and broader-spectrum performance compared to standalone Shieldex.

Grass control in small grains is a game of strategy—especially in the face of mounting resistance. Understanding not just your herbicide’s group, but its chemical family, can make all the difference in product performance and long-term sustainability.

Rotate smart. Scout often. And don’t hesitate to reach out to your Horizon Resources Agronomist if you want to talk through options for your fields.

Kyle Okke, CCA

Agile Agronomy LLC & Agronomists Happy Hour

Diagnosing Bare Patches and Uneven Emergence

As we have been scouting fields this spring, a common theme is areas of poor emergence. They have ranged from small circular areas to large linear patches and are frequently, but not always, associated with areas of high residue. One might assume that the crop is just struggling to get up out of the residue and in several cases that was the case, but not always. It is important to diagnose the problem so that the appropriate solution can be found.If cutworms are the culprit, timely intervention is critical. A foliar insecticide can prevent further damage, making this a time-sensitive issue. Warm weather spurs insect growth, so it’s possible we would not have seen much damage until this past week. Cutworm larvae feed on seedlings starting in the beginning of May through June. Dingy cutworms are the first to emerge as partially grown larvae, followed by species that over-winter as eggs (red-backed cutworm) and then finally species that migrate into our state in the spring (black cutworm).

Dingy cutworm, red-backed cutworm, black cutworm

To diagnose this issue, look for plants that have been cut below, at or above the soil line. The top part of the plant may be dead on the ground next to it although with the windy conditions we have had they could have blown away. You can dig around the plants to look for the cutworm larvae but this can be difficult as they migrate several inches down into the soil during the day. They may be easier to find later in the evening when they come to the surface to feed. Cutworms tend to cut down a row, so the field pattern might also help you figure out what is going on.

Corn, canola, lentils, field peas, sunflowers and soybeans are more susceptible to cutworm damage than small grains, because they are unable to compensate through tillering. Action thresholds for insecticide were discussed in the May 5th issue of our newsletter. In corn economic damage can occur with as little as 3% of plants cut, whereas soybeans can tolerate up to 20%. Economic thresholds are also based on cutworm size and you may see a range of sizes in a field. If most of the larvae are small (<¾ inch) then they are still actively feeding and treatment is warranted.

Cutworm damage has been observed in canola in southwest ND this spring, and in previous years in field pea and corn as well in our area. Several insecticide products are labeled for cutworm control. Use the higher end of the labeled rate for better control and longer residual activity. Since cutworms must consume treated tissue to be killed, ensure high water volumes for thorough coverage.

When you are digging around plants to diagnose cutworm damage, you might end up finding wireworms instead. The plant damage may look similar, but the wireworms are not hard to find. Cool, wet conditions favor wireworm feeding so it is not surprising that we have observed wireworms in lentil and durum this spring (pictures below).

Unfortunately, there are no foliar insecticide treatments for wireworm but you can manage this pest in the future by using an insecticide seed treatment. It may not eliminate wireworm in the field in that season, but will reduce yield loss due to feeding damage. Wireworms have a life cycle spanning two to six years so this problem will require long term management. Teraxxa and Teraxxa F4 contain an insecticide that was designed to reduce wireworm populations over time.

Poor stands caused by Pythium seed rot can resemble insect feeding above ground; however, unlike damage from cutworms or wireworms, affected seeds or seedlings are often completely missing. In cases of severe infection, the seed may be fully decomposed by the pathogen. If a fungicide seed treatment was used, Pythium is less likely to be the cause. All seed treatments we recommend contain an active ingredient effective against Pythium. The only exception would be if a resistant strain were present, but fungicide resistant Pythium has not been documented in North Dakota to date.

Bare patches or slow emergence due to heavy residue has been very common this season. In some cases the seed has been planted in the residue instead of the furrow. In others, the seed was properly planted but the seedling is just taking longer to emerge. This may be due to the physical barrier of the residue or lower soil temps in those areas. Uneven emergence is making spray decisions a challenge this spring when the crop is already progressing slowly due to cooler temperatures. Be sure to stage crops in high-residue areas to avoid applying herbicides too early.

Additionally, heavy residue can lead to fertilizer tie-up. Microbes use nitrogen to decompose residue, reducing availability for the crop.

Residue management will be increasingly important in future seasons to avoid both nutrient deficiencies and emergence problems.

Dr. Audrey Kalil

Agronomist/Outreach Coordinator

Julia Seiller

Agronomist, Fairview Location

Hurry Up and Wait—Field Scouting Update

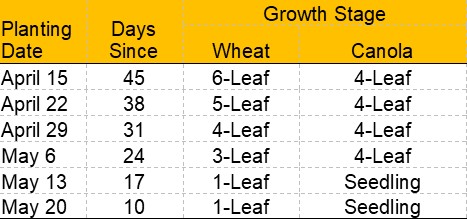

While the early seeded crop might be ready for in crop spray, lack of warm weather continues to suppress crop development in canola, durum and spring wheat. Below is a table from NDAWN showing the growth stage of wheat and canola based on the number of growing degree days. The base temperature for growth of canola is 41°F and for wheat its 42°F, although 32°F is used for the wheat growing degree day (GDD) model. Growing degree days are calculated by subtracting the base temperature from the daily average air temperature. While temperature is the main driver for plant growth, water and daylight also impact growth rate. Lack of sunshine during the first half of the month also likely delayed crop development.

Several different growth stages will be present in the field simultaneously, so while some of the crop might be at 3-leaf, other plants might be at 2-leaf so waiting until 5-leaf ensures that all of the crop is at the correct timing.

Wheat growth stages (modified from SDSU).

We discussed the importance of managing Canada thistle in the last newsletter, and if you are using Stinger or Stinger HL to manage this weed in canola you need to wait until 2-leaf. Depending on the severity of the Canada thistle infestation compared to other weeds like wild oat or Russian thistle, you may not want to wait that long. Canola yield is highest if weeds are well controlled between emergence and six-leaf.

Make sure to check for flea beetles as we have observed some fields with feeding damage (picture below), however it has varied greatly from field to field. Some fields have had little to no flea beetle feeding. Canola yield can be reduced by feeding up to 6-leaf, and if you planted late April or early May then the insecticide seed treatment is no longer providing protection.

The weeds are starting to catch up with the crop and most of the common weeds that we deal with have emerged. Kochia that had not emerged prior to burn down is now up along with wild buckwheat and Russian thistle. Broadleaf weeds are anywhere from cotyledon stage to 2 inches tall. Wild oat is 3-4 inches tall and foxtails are around 0.5 – 1 inch tall.

Wild oat and wild buckwheat. Pictures taken May 24th.

Fairview Agronomist Julia Seiller has been scouting corn and soybean fields, which are showing the stress from lack of sunlight and low temperatures (picture below taken May 30th).

We’ve got some more rain predicted and mild temperatures in the forecast so this spray season will likely be a practice in patience. If you need any help with crop staging just let us know.

Dr. Audrey Kalil

Agronomist/Outreach Coordinator

Generics…..Do they work the same?

When commodity prices are low, growers are looking for any way possible to cut expenses and one of the first targets is to use cheaper crop protection products. I fully understand this, but my warning is that you do not trip over quarters trying to save nickels.I was asked this question this week, “Do generics work the same as the original branded products”? My answer and honest opinion is simply, no they don’t. The labels usually mirror the original branded products labels, and they state the active ingredients by percentages and by pounds of active per gallon of product, but what is not stated or regulated is the surfactants used to help get the products into the weeds or plants. This is the main difference between generics and is the way the generic companies can cheapen up the look alike products.

It costs a lot of money for the original manufacturer to get that product through testing and registration and that company wanted/needed to make enough margins on that product to make it worthwhile to spend that money. To get those products onto the market, they were not going to skimp on the surfactants or any non-regulated products that would affect the efficacy of the product or it could impact the sales volumes. Once a product is off patent and is available for the generic market, those products are not quite as dependent on capturing enough money to pay for the original registration investments, so as long as they are using the same active and have mirrored the original label, one of the ways they can make more money is by using lower quality, cheaper surfactants.

This has been very apparent to private crop consultants that I have visited with through the years that do not sell crop protection products and leave it up to the grower as to where he buys his products. When a crop consultant makes recommendations based on the active ingredients, or in cases where the customer is buying from a source that promotes generics exclusively, the grower might end up using products that don’t quite work as well. I had one consultant tell me he had dealt with an absolute wreck after the grower sourced the cheapest generics he could find, and they did not provide even half the weed control that was expected. When asked what he sprayed, the grower showed him the list of generics, and the consultant was not really happy since it put his reputation on the line too.

In the end, you would need to save a huge amount of money with generics to make a difference in your operation. The way I always try to relate it is that you have the cost of producing each bushel of crop you are raising. If you spend $25 per acre on your post emerge application on wheat or durum and you produce a 40-bushel yield, that costs you $.625 per bushel in your cost of production. If you can save 20% or a total of $5 per acre, you will only be saving $.125 per bushel in your cost of production. If you lose weed control with a weed like wild oats, kochia or wild mustard, you could easily lose 5 to 10 bushel per acre that could cost you way more than your total herbicide application costs in the first place.

I have said many times that the most expensive weed control program is the one that didn’t work. With pricing pressure on every dealer in the country competing with business models that offer no value or services, we are all forced into offering generic products. Almost all of the products that we use are offered as generic products already, so it is becoming a larger part of every dealer’s sales volume. Back to the question, “Do generics work the same as the original manufacturer products”? The active ingredients will more than likely work the same, once the product is into targeted weed or plants and that is dependent on the quality of the surfactants or non-regulated products included in the jug. I can take this even a step further and I will tell you I trust some companies making generics more than I trust others. We sell more and more generic products each year as products come off patents and growers request the cheapest option available. I would rather see branded products being used as I am more confident in the results, but if you are comfortable with having no support if the product does not work, generics are available if you want to take the gamble. It might end up costing you $40 per acre in yield if you lose weed control to save $5 per acre in the cost of the products and that is a gamble.

John Salvevold, CCA

Agronomy Division Manager

To hear about the status of fertilizer markets and more check out the latest episode of the “On the Horizon” podcast with Agronomy Division Manager, John Salvevold.