Agronomy Update

May 12, 2025

In Crop Herbicide Timing in Canola

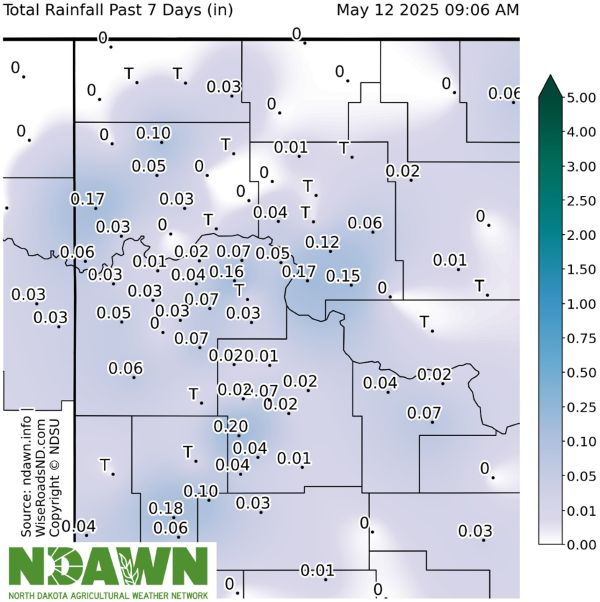

With the crop going into cool soils and the lack of warm days, canola has been growing slowly. A canola field we were scouting early last week was at one leaf, 3 weeks after planting. As soon as you can see the rows in the field, it is time to think about your in crop herbicide application. Kochia, Russian thistle, Canada thistle, field bindweed, wild buckwheat and wild oats have already emerged, and the longer they are allowed to grow the more resources they consume in both water and nutrients, competing with your crop.Research was conducted in Western Canada across 10 canola fields in 1999 and 2000 to evaluate the effect of weed control timing on canola yield. They consistently found that yield was highest when weed control was early, and there was a yield penalty to delaying weed control until the 6-7th leaf stage. The graph below summarizes their results. Yield was highest where weed control was implemented at the 1-2 leaf stage, and decreased as the herbicide was applied at the 3-5 leaf stage and even more so at the 6-7th leaf stage.

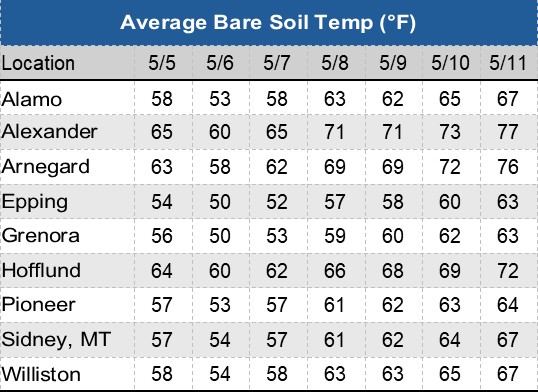

Another study conducted at the University of Manitoba found that canola had to be kept weed free until the 4-6th leaf stage to prevent greater than 10 percent yield loss. This equated to roughly 17-41 days after emergence depending on the seeding date. The diagram below summarizes herbicide timing relative to yield protection.

While weeds might be small right now, we can still control them with adequate water volumes. That would be 15 gal/ac for Liberty and 10 gal/ac glyphosate. Remember that Liberty works best on hot, sunny, humid days.

This season we will be transitioning from the Liberty 280 SL to the Liberty Ultra so make sure you know which product you’re using as the use rate differs. All generic Liberty today is a mixture of the active (L) and inactive (D) glufosinate ammonium ingredients. Liberty Ultra contains a higher percentage of the active L-glufosinate ammonium which means it delivers more effective active ingredient per dose than the old formulation. A use rate of 19 oz/ac for the Liberty Ultra will deliver the same control as 29 oz/ac of the Liberty 280 SL. That is about as low as you’ll want to go in order to get adequate control of our weed spectrum out here. Regardless of the Liberty product you are using the water conditioner is still required, either as dry AMS or Class Act NG (2.5% v/v).

This is also the timing when we are considering a foliar insecticide for flea beetle control. While scouting canola last week we found a field where the flea beetle feeding had moved from the field edge to the field interior and seemed to be increasing in severity. Another field had no evidence of flea beetle feeding damage. Your seed treatment should provide 3-4 weeks of protection unless flea beetle pressure is extremely high. After that period of time if the crop is still less than the four leaf growth stage you could see yield loss due to feeding damage. The latest NDSU Crop and Pest Report and Canadian Canola Council has more details about making flea beetle spray decisions.

Dr. Audrey Kalil, Agronomist/Outreach Coordinator

Heat Canker Symptoms in Wheat

Rapid swings from cool to hot temperatures can cause peculiar symptoms in the field, especially in young wheat seedlings. Sometimes mistaken for insect damage or disease, these symptoms are actually due to heat canker (picture below).

In the earliest growth stages, wheat seedlings have very tender tissue. When temperatures rise suddenly, the soil surface heats up and "burns" the leaf at the soil line, leaving a scar or "canker." As the plant grows, this cankered area moves upward, which scouts might notice while checking for weeds or pests.

Fortunately, heat canker is purely cosmetic and does not affect yield potential. It is simply a springtime phenomenon in early wheat growth during periods of large temperature swings, like those we've experienced recently.

Kyle Okke, Crop Consultant, CCA

Agile Agronomy LLC & Agronomists Happy Hour Podcast

Express Herbicide for Burndown for Peas and Chickpeas

New for the 2025 growing season, Express® Herbicide with TotalSol® Soluble Granules is now labelled for a burndown application with a 1-day plant back to field peas and chickpeas when used at 0.25 oz/A. This will be especially helpful for growers battling early emerging and tough to kill weeds such as narrowleaf hawksbeard, dandelion, mustard spp., Canada thistle and other perennial and winter annual weeds that may be already emerging this spring.Unique to FMC SU herbicides is the TotalSol® Soluble Granule formulation which makes Express® herbicide and the Affinity® brand herbicides the only SU products on the market able to dissolve into a complete solution with water in the spray tank. This means less tank clean out and significantly less risk of sprayer contamination or herbicide hang up in the tank/booms when compared to other SU products that are DF (dry flowable) formulations. This provides an extra level of safety when transitioning to a field with a sensitive crop.

Now with this benefit of the TotalSol® formulation comes a few changes to the norm and steps we need to take to ensure tank mixing with other products is done correctly.

Suggested mixing order for Express® herbicide being used with glyphosate burn-down

1. Begin adding water to the tank

2. Add dry FMC SU product to the tank when the tank is 1/3 full of water

3. Agitate while adding the remaining water.

4. Agitate while adding the remaining water. The TotalSol® granule will take slightly longer to dissolve, so allow~10 minutes to get it in to solution – longer if the water is cold

5. As soon as possible, add Basic Blend (Linkage) at a rate of 1 gal/100 gal

6. Agitate for 1 more minute

7. Add AMS** (if using)

8. Add other products you may be using in the standard "APPLES" order (see NDSU Weed Guide for more details)

9. Add glyphosate last

** Linkage contains N, so additional AMS is not required when using 1gal/100 rate of Linkage

Ryan Hunt, Technical Services Manager, FMC

Signs of Winter Kill in Alfalfa

Last Tuesday I was out looking at an alfalfa stand and it was evident that the problem was winter kill. An initial sign of winter kill is that areas affected are slow to green up (picture below). If some fields, or areas of a field, are turning green while others remain brown, those plants might have been winter killed. To confirm that diagnosis, you can dig up plants to roughly four to six inches in the healthy and brown areas to compare how the roots look.

Photo Credit: SDSU Extension Service, Sara Bauder

Healthy roots will be firm and white, while root or crown rot caused by disease will be black or dark brown. Below are pictures from the affected plants in the winter killed field. All the roots are severed at the same depth, and they are a light brown color due to the fact that they have been dead several months, but not the dark brown associated with root disease.

Winter kill in alfalfa is caused by one of two things:

- Ice Suffocation - When snow melts and the water runs into low areas of a field, it can refreeze into a sheet of ice on the soil surface. This ice prevents oxygen from reaching the alfalfa plants beneath it. Without oxygen, the plants suffocate and die. This is one of the most common causes of winter kill in alfalfa and it usually results in large, noticeable patches of dead plants.

- Root Severing - Saturated soils freeze rapidly with little snow cover, resulting in the ice expanding the soil to the point that the roots physically snap in half.

The second, less common, cause of winter kill is what occurred in this field. I’ve only ever seen this type of winter kill once before, on the Milk River on clay soils, when they received 10-12” of rain in August of 2014 right after they had flood irrigated. Then it went from 65 above to 17 below in 24 hours in November that year, even freezing the evergreen needles in Billings. In the field I was evaluating last week, the pivot was run later than normal, so there was likely a full soil moisture profile going into winter and we had very little snow cover to insulate the soil. These conditions are similar to what I saw in 2014.

Root severing is unrelated to characteristics of the alfalfa variety such as winter hardiness or other traits, as it is entirely environmental.

Freezing of the soil severs the roots. Following a winter kill event, if enough of the field has survived take extra care of the remaining stand. Leave extra time before cutting to allow the plants to recover and re-develop roots. Fertilize if a soil test indicates a deficiency. If you want to fill in patches consider inter-seeding hay barley or oats early, or a warm season annual grass like millet or sorghum sudan after the first cutting.

Curt Droogsma, CCA

Sales Development Manager Winfield United

Tolvera Herbicide: Adding a New Active to the Cereals Market

I hope everyone has had a safe spring so far in 2025. As we gear up for another busy spray season, I wanted to share with you all some tips when spraying Tolvera herbicide in your cereal crops this year. Tolvera herbicide is a new product for 2025 and contains group 6 (Bromoxynil) and a group 27 which is new to the cereals market

(Topyralate).

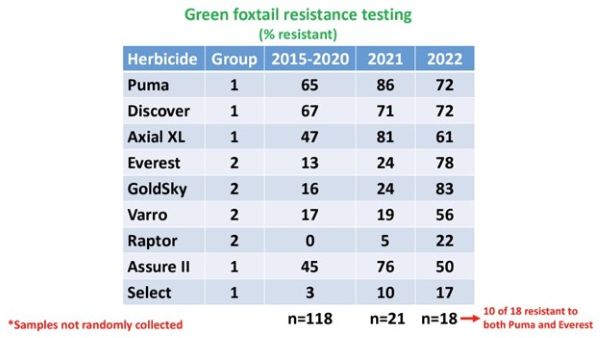

We all have experience with Bromoxynil, but what does Topyralate bring to the table? Topyralate brings control over a broad selection of broadleaf weeds like pigweed, ragweed, lambsquarter, kochia and marestail to name a few, but Topyralate also controls some grass species. Tolvera will control green and yellow foxtail as well as barnyardgrass. This is the first time that we have been able to utilize a group 27 on certain grass species which will be very important moving forward as we see more group 1 and group 2 grass resistant species.

Source: Brain Jenks Wild World of Weeds 2024

Tolvera herbicide is labeled in winter wheat, spring wheat, durum and barley. The use rate ranges from 11oz/ac up to 14.7oz/ac. In my experience, the higher rate would be needed when there is tillering foxtail species and no other grass herbicide tank mixed in with Tolvera. I would also recommend a higher rate if broadleaf pressure is high as well.

This is a new active in our market, and tank mixing appropriately will ensure the longevity of this active. Tolvera does not have control on wild oats, so we need to look at different tank mix options where this applies. Tolvera is an EC herbicide and is extremely easy to tank mix with. When using Tolvera, we require a MSO in the tank at 1% v/v. If we add a second EC into the tank, then we need to lower the MSO rate down to 0.5% v/v.

As stated above, if we are tank mixing another grass herbicide into the tank, we would then follow that second grass herbicides’ adjuvant recommendation. For example, when tank mixing OpenSky with Tolvera we would use an AMS at 1.5 lbs/ac OR a basic blend (Linkage) at 0.5% v/v. If you are tank mixing with a group 1 grass herbicide like Rezuvant which contains pinoxaden, then there is no need for an adjuvant, but a NIS could still be used in this scenario.

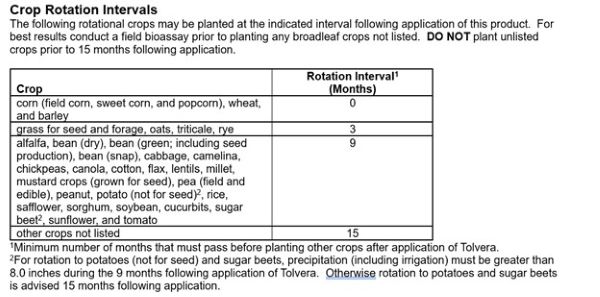

A great benefit of Tolvera EC is the rotation flexibility for pulse crops. We applied 3x the labeled rates of Tolvera in trials in eastern Montana and had zero carryover issues going back to peas or lentils 10 months later compared to a competitors’ HPPD at a 2x labeled rate, which showed a noticeable stand loss. Tolvera will not only give you peace of mind when controlling weeds in this years’ crop, but you can be confident in keeping your cropping plans open for the following year.

Reach out to your Horizon Resources Agronomy location with any further questions. I hope you all have a safe and successful 2025!

Seth Larson

Territory Manager – Northwest North Dakota

Pay Attention to Spray Water Volume

Every crop protection product we sell comes with a product use label. One of the most important parts of the label is the required water volume or carrier volume as stated on the label. Each product will perform best when used as required at the recommended water volumes stated on the product label. One product might work better at a lower water volume than another product, which might require using 3 to 4 times as much water. Higher water volumes are usually used with products that require complete coverage over the surface of the weed or crop foliage in the case of fungicides, because the product will not translocate or move through the plant or weed.Thirty plus years ago, growers were spraying really low volumes of water. As low as one to two gallons per acre. At the time, this was still working mainly because of the products that they were spraying translocated through the weeds readily and you could kill a weed with a small amount of product. These products were relatively new at the time, and they all worked really well to kill weeds. As we have continued to use products over and over for decades now, a lot of the older chemistries have very little efficacy and there is a lot of resistance or tolerance to some products.

As the product mix has changed, we have a lot of products being used that do require a larger water volume than the 2,4-D’s or glyphosate products of past years. In the early 2000’s we started using a lot of bromoxynil products like Bronate which have evolved to generic products like Bison. This chemistry requires at least 10 gallons of wa- ter per acre mainly because it is not mobile in the plant and you need to cover the weed surface to get the best results.

Lower water volumes might work in certain conditions, but if you have a lot of weeds or weeds that are getting larger, you need to follow the label and use the higher water volumes. The end result of not killing every weed in the field is that the weeds that are being sprayed with sublethal rates of chemical/water develop a tolerance to that product and the seed produced will become even more tolerant which leads to resistance.

Soil applied herbicides will usually require a minimum of 10 gallons of water per acre and that is mainly to get good coverage of the active ingredients over the entire field. Prowl H2O actually works best at 15 to 20 gallons of water per acre, so this eliminates the ability to tank mix with glyphosate for a burndown. Glyphosate is better at 5 gallons than it is at 15 gallons, and we have seen antagonism at high water volumes when mixed with Prowl H2O.

Desiccants like paraquat or Gramoxone need at least 20 gallons of water as that product does not move in the plant at all and will only burn the foliage that it comes into contact with. I have seen Rely sprayed on potato vines at 20, 30, 40 and 50 gallons of water per acre and it didn’t even look like it was sprayed at 20 gallons per acre. This was done with one of our earlier self-propelled sprayers with a 500- gallon water tank getting 10 acres per load!

Spray tips will also make a difference in how the water hits the target. If you are spraying a contact herbicide with a huge droplet from an air induction tip at 4 gallons per acre when 10 gallons is recommended, you should change your herbicide choice because this is making a bad program even worse. The way to look at contact herbicides, all fungicides and desiccants is that you need to paint the weed or plant surface. Even a flat fan nozzle will be more like a paint roller in this example, while a large droplet air induction tip would be like painting with a small 1” paintbrush in comparison.

Just as important as the water volume is the quality of your water along with surfactants used with the products you are spraying when needed. If you are using really hard water, there is a greater chance of tie up of the chemical in your tank, before it even reaches the leaf surface of the weeds you are trying to kill. If you have questions about your water, get it tested.

Surfactants are the ticket into the plant surface of the weed or crop foliage, so this is also very important. The main difference between branded glyphosates like RT-3 and Roundup Powermax versus any generic product is the quality of the surfactant. Cheap products are cheap because they use cheap surfactants and, in some cases, no surfactants at all. Not that I would suggest this ever, but you can probably cut the rate of branded RT-3 or Roundup Powermax in half and it will still give you better weed kill than some of the cheap generics that are sold without surfactants. This is another case of you get what you pay for, and in the end, the difference in the price per gallon of glyphosate is even less than how much my wife can save on lettuce at one grocery store versus another.

Water volumes are very important in how the products you are spraying actually work and are not written on the labels just as an inconvenience to growers. When water volumes are cut, you are taking a chance of spending money on weed control that does not control the weeds, and you are promoting tolerance and resistance to the products that are still available to us. With the herbicide resistance becoming a bigger problem every year, we have started a program with a lot of our growers to help them manage their rotations along with record keeping for all of their applications. Talk to any one of our Sales Agronomists if you are interested in working with our intense crop scouting/record keeping program.

John Salvevold, CCA

Agronomy Division Manager