Agronomy Update

Mar 19, 2025

Meet Julia Seiller: Horizon Resources’ Newest Agronomist

Episode 10 of season 2 of the On the Horizon podcast introduces Julia Seiller, the newest member of the Horizon Resources Agronomy team. Julia joined the Fairview location last October and has hit the ground running with soil sampling and learning our FarmQA program. Get to know Julia by listening to the episode on YouTube or wherever you get your podcasts.

Fungicide Seed Treatment Considerations

Seed applied fungicides protect your crop from pathogens that live in the soil as well as pathogens that survive on seed and infect the germinating seedling. There are several specific pathogens that I will discuss, but they can be broadly split into two categories: fungi and oomycetes (water molds). The reason why this is important is that different active ingredients are effective against fungi vs oomycetes and we need to choose products that will protect us against both groups. The same can be said for pathogens that survive on the seed. It is important to select products with active ingredients that have been evaluated for efficacy against seed-borne disease.

The oomycetes are termed water molds because they tend to cause problems under wet conditions. The reason for this is that they produce swimming spores that move through the soil to attack seeds and/or plant roots. That is why we expect to see more widespread issues with oomycetes when we have good soil moisture and rainfall events occur just after seeding and as the crop is emerging. While this is true and severe disease usually occurs in an abnormally wet year, that does not mean zero disease occurs in a normal year. It does not take a lot of moisture for these pathogens to cause problems, particularly in a field with a history of disease issues.

Pythium is probably the most widespread oomycete pathogen and can cause yield loss in all of the crops that we grow. It is not considered host specific, however, chickpea in particular can get hammered by this pathogen. The large, non-pigmented seed is the perfect meal for seed rotting Pythium and heavy stand losses can occur even under dry conditions. Pythium is primarily controlled through fungicide seed treatments. Phytophthora is an oomycete that can cause pre-emergence and post emergence damping off (plant death) in soybean. This disease can be controlled through a combination of genetic resistance and fungicide seed treatment.

Be aware that active ingredients differ in their ability to control Pythium or Phytophthora and so for soybean, you need to make sure your seed treatment provides protection against both. For peas, lentils and chickpeas we are primarily focused on Pythium. Metalaxyl (Allegiance), mefenoxam (Apron), picarbutrazox (Vayantis) and ethaboxam (Intego Solo) are all active ingredients which can provide protection against Pythium and Phytophthora. Oxathiapiprolin (Orondis) provides protection against just Phytophthora. Picarbutrazox is a new active ingredient and is still being evaluated by University researchers, but it does appear to provide protection against metalaxyl/mefenoxam resistant Pythium. Another oomycete you are probably familiar with, Aphanomyces euteiches, which causes root rot, is not controlled by any products that are on the market today. All of the above pathogens are found in the soil, and can cause disease even if healthy, disease free seed lots are planted.

When we are discussing the management of soil fungal pathogens, Rhizoctonia and Fusarium are typically the primary focus. Rhizoctonia solani is the species that is problematic in our region, and it is further divided into AG groups which can be specific to certain crops. For ex- ample Rhizoctonia solani AG2-2 IIIB is known to cause disease in sug- ar beet, dry beans and soybeans. There are AG groups that will attack just about every crop we grow including pulses, wheat and canola.

The image below was taken by NDSU Soybean Pathologist, Dr. Wade Webster, showing Rhizoctonia damage on soybeans in 2024, demonstrating that untreated seed can result in stand and crop loss. There are several active ingredients with efficacy against Rhizoctonia including Fluxapyroxad (FRAC 7), Sedaxane (FRAC 7), Azoxystrobin (FRAC 11), and Mefentrifluconazole (FRAC 3).

Early season soybean stand loss due to Rhizoctonia

Soybean damping off

Fusarium is different from Rhizoctonia in that it prefers warmer temperatures and thus can infect later into the season. For that reason, seed treatments are less effective against Fusarium diseases like Fusarium root rot in pulse crops. When planting into warmer soils, however, an active ingredient which provides good protection against Fusarium may provide a yield advantage. That said, do not expect season long control of root rot. Active ingredients like Fludioxonil (FRAC 12), Mefentrifluconazole (FRAC 3), and Prothioconazole (FRAC 3) are considered good against early season Fusarium infection.

Depending on what crop you are growing there may be other seed or soil pathogens to consider when selecting a seed applied fungicide product this spring. For example, Ascochyta for pulse crops or loose smut for wheat/durum. Seed treatment is also used to manage sudden death syndrome in soybeans but thus far that has not been detected in our region. Testing pulse crop seed for seed-borne pathogens can help determine if an active ingredient for Ascochyta is needed (symptoms in right picture below). Given the high level of susceptibility of chickpea to this disease, regular use of a seed treatment for Ascochyta is likely beneficial. Wheat or durum fields that experienced a lot of loose smut (left image below) problems last year will carry those spores on the seed and the plant will be infected if seed is not treated.

So, at a minimum, your seed treatment product should have activity for Pythium, Fusarium and Rhizoctonia to ensure protection against the most common soil pathogens. Based on the above, you can see why fungicide seed treatment products contain so many active ingredients. A product like Rancona Summit (Ipconazole + Metalaxyl) will provide you with protection against Pythium and gives you one mode of action against the soil-borne fungi. If you aren’t sure about treating your peas or lentils this is a good place to start. A product like Vibrance Maxx Pulses RTA, has active ingredients with high levels of activity against Rhizoctonia (Sedaxane), Fusarium (Fludioxonil), and Pythium (Mefenoxam), while protecting your pulse crop against seed-borne Ascochyta (Thiabendazole).

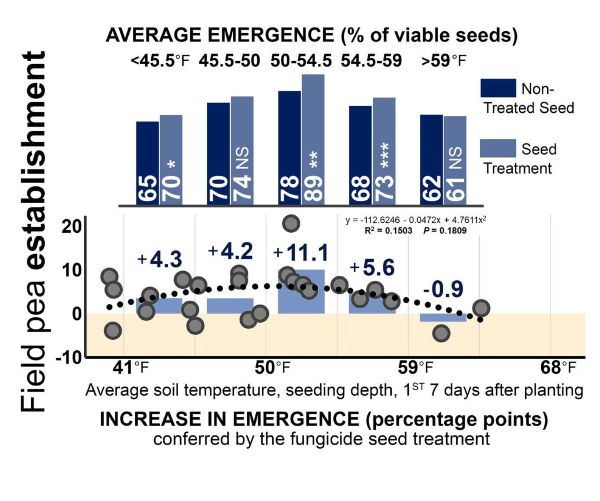

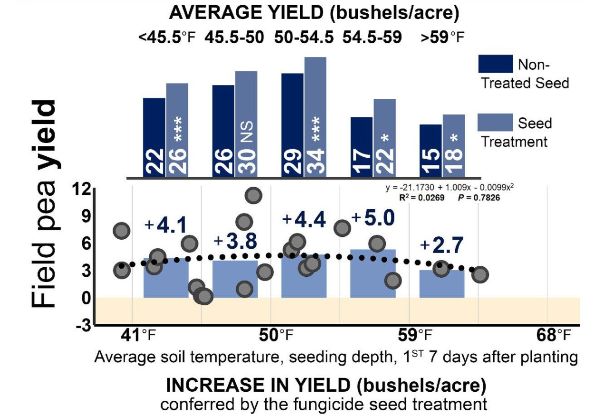

Crop rotation is an important first step when it comes to tackling soil-borne disease so fungicide seed treatment should always be used in conjunction with, and not as a substitute for, good crop rotations. Therefore, if it is necessary to plant small grains onto small grains year after year, or have tight rotations of pulse crops, you will likely see a stronger response to a fungicide seed treatment. Below are charts from Dr. Michael Wunsch, NDSU Plant Pathologist, demonstrating the increased stand and yield response to a fungicide seed treatment (Obvius) when peas were planted into a field with a long history of pea and lentil production. This data is an average of studies conducted across nine site-years including Williams County. In this case, planting early into cool soils in combination with a fungicide seed treatment minimized stand loss and maximized yield. Yields overall were still fairly low, showing the importance of adding extended crop rotation to the soil-borne disease management toolbox.

Of course fungicides are not the only products we apply to the seed and I have not yet discussed insecticides, which are regularly included in retailed canola, soybean and corn seed treatments. So what about our small grains and pulses? That decision really depends on the level of stand loss you see due to wireworms and cutworms and how concerned you are about potential early season grasshopper feeding and nodule feeding on peas by pea leaf weevil. If you want to cover your bases consider Lumivia®, a Corteva product, because this product has broad activity against armyworm, cutworm, wireworm, grasshoppers and pea leaf weevil. Last year, for pulse crops, we paired Lumivia with Cruiser Maxx Vibrance Pulses which allows us to use the lower rate of Lumivia and provides the same soil and seed borne pathogen protection as Vibrance Maxx Pulses RTA.

I have been asking around about what folks use to treat seed on the farm and I have been told the following two products work well if you are interested in exploring that option:

Zag Seed Treater Applicator

Graham Seed Treating System

We do have a seed treatment facility at our Fairview Agronomy location. So reach out to Bruce or Julia if you are interested in having your seed treated this spring.

Dr. Audrey Kalil, Agronomist/Outreach Coordinator

Commodity Groups Active in DC

With a new administration in the White House there are always a lot of changes and this one is no different. Commodity groups have been traveling to Washington D.C. in force to advocate for grower issues with legislators and regulators. I joined the USA Dry Pea and Lentil Council (USADPLC) and American Pulse Association D.C. mission on behalf of the Northern Pulse Growers Association in February where we spent the week meeting with policymakers to discuss issues affecting the U.S. pulse industry. There were 29 people total on the mission including pulse growers and industry representations from Bush Beans, Puris and AGT, along with the USADPLC team. Together we were able to meet with 81 congressional offices over the five day trip, including House and Senate Ag Committee representatives, and several federal agencies.

Meeting with House Ag Committee Staff

USAID was a hot topic that week and remains to be important to the pulse industry. Approximately 10-15% of U.S. pulse crops flow through food aid programs and thus anything affecting them would impact pulse markets. In early February when the program was halted, there were pulse crops stuck in ports and in our meetings we brought that to their attention. We also highlighted some of the trade relationships that impact the pulse industry and barriers to trade such as aging infrastructure at key ports. For reference, approximately 60% of U.S. pulse crops are exported.

Of course we discussed the Farm Bill and changes that would benefit the pulse industry. That included lower premiums, dual enrollment in ARC/PLC, and a fava bean/lupin exemption to base acres. When asked about the possibility of getting a new Farm Bill in 2025, the responses ranged from “unlikely” to “we work really hard to get it done.”

Meeting with Senator Hoeven (R-ND)

Federal funding has been really important for pulse crop research and both foreign and domestic market development. The addition of these Federal funds makes your check off dollars go a lot further. The USA Dry Pea and Lentil Council relies heavily upon the Market Access Program and Foreign Market Development Program to fund their oversees marketing offices. The Pulse Crop Health Initiative has funded millions of dollars in nutrition and agronomic research, and the Pulse Quality Network funds three labs located in ND, MI, WA, providing buyers and industry members with key information about the quality of US grown pulses. There is also a USDA-ARS facility in Pullman, WA dedicated to maintaining and advancing genetic resources for pulse crop breeding, which houses a unique seed collection of pulse varieties and wild relatives collected around the globe. We shared the importance of these resources to the pulse industry with policy makers so that they continue into the future.

I hope this highlights the importance of being an active participant in grower organizations and that you consider getting involved when board positions open up and opportunities arise to go on D.C. missions. To quote a phrase you may be familiar with, “If you’re not at the table, you’re on the menu.” As a small but vital industry, these efforts are particularly critical.

Dr. Audrey Kalil, Agronomist/Outreach Coordinator

When Is the Right Time to Plant Corn?

With spring right around the corner, it’s the perfect time to review best practices for planting corn, including the right timing, seeding depth and the importance of starter fertilizers.

Corn should be planted into soils that are near 50°F and rising. Planting into cold soils can cause a phenomenon called “chill imbibition”, which occurs when corn seed absorbs very cold water during the first 48 hours a corn seed is in the ground. Corn seed cells are fragile during germination, and cold water can cause those plant cell membranes to rupture, leading to the loss of vital nutrients. This disruption can cause slow, uneven development and poor vigor, ultimately impacting your yield. There is no need to be in a hurry to plant. The very early days of spring don’t provide enough heat units to encourage much in terms of corn growth. It’s worth waiting for soil temperatures to trend in the 50s on average, or higher, as this will promote better stand establishment.

Correct seeding depth is critical for corn. As you might already know, the sweet spot for corn planting depth is between 2 to 2.5 inches. Seeding too shallow or too deep can have its issues:

Shallow Seeding (1.5” or less)

- Exposed to soil temperature fluctuations

- Root development will be impacted, leading to lodging

- Colder soil temperatures

- Slower germination

- Uneven emergence

- Reduced vigor

- More susceptible to disease and wireworm

Kyle Okke, Crop Consultant, CCA

Agile Agronomy LLC and Agronomists Happy Hour podcast

Wild Oat Resistance Testing

At MonDak Pulse Day last month, Dr. Brian Jenks, NDSU Weed Scientist, shared some results from his wild oat resistance testing and advice on how to manage fields that have these weed populations.

Below are the results from two wild oat samples that Dr. Jenks tested in the greenhouse this winter.

| Herbicide Tested | Group | Sample 1 | Sample 2 | |

| Puma | Fenoxaprop | 1 | R | R |

| Axial XL | Pinoxaden | 1 | MR | S |

| Everest | Carboxamide | 2 | R | S |

| GoldSky | Pyroxsulam/Florasulam | 2 | MR | S |

| Varro | Thiencarbazone-methyl | 2 | R | S-SR |

| Raptor | Imazamox | 2 | S-MR | S |

| Assure II | Quizalofop | 1 | R | MR |

| Select | Clethodim | 1 | S | S |

He planted out the seeds and then sprayed the emerged plants with Group 1 and Group 2 herbicides with the appropriate adjuvants:

- Puma (0.67 pt) Axial (16.4 fl oz)

- Everest 3.0 + Basic Blend (2 fl oz + 1%) GoldSky + NIS (1 pt + 0.25%)

- Varro + AMS (6.85 fl oz + 2.5 gal/100gal Bronc)

- Raptor + NIS + 28% N (4 fl oz + 0.25% + 2.5 gal/100gal) Assure II + COC (8 fl oz + 1%)

- Select2EC + COC (6 fl oz + 1 %)

SR = slightly resistant (growth was reduced significantly, with good crop competition may not be competitive produce seed)

MR = moderately resistant (growth was reduced slightly, but will still be competitive and produce seed)

R = resistant (looks similar to untreated)

Sample 1 was resistant to all the group 2s tested as well as all of the group 1s herbicides except clethodim. Sample 2 was still susceptible to group 2 herbicides, Axial and clethodim but was resistant to Assure II and Puma. These results emphasize that we need to diversify the tactics we use against these populations or we will quickly lose activity of our go to products. Below are some suggestions Dr. Jenks proposed to tackle the issue of herbicide resistance in wild oats.

- Incorporate Zidua or Anthem Flex (Group 15) into your fall herbicide program

- Incorporate canola into the rotation (Round Up Ready or Liberty)

- Stay out of wheat/durum for 3 or more years when resistant wild oat populations are high

- Plant barley in these fields, it is very competitive with wild oat

- Increase seeding rates

- Always use full rate of Liberty or clethodim and spray wild oat when its small (2-3 leaf stage)

If you are having problems with wild oat you can collect seed and send them into Dr. Jenks directly or we can help you send them in for testing. Wild oat seeds can last 5 to 10 years and so it’s a long-term project to get rid of resistant populations once they are in your fields. As usual, an ounce of prevention is worth a pound of cure.

Getting the Most out of Your Fertilizer

While we aren’t quite there yet, folks are starting to ask about spreading fertilizer, and planting will be here before we know it. It’s a good time to talk about how we can get the most out of the nitrogen we spread and the phosphate we apply in furrow.

With sufficient moisture, applied urea converts to ammonium bicarbonate within approximately 48 hours. The ammonium (NH4+) can then convert to ammonia gas (NH3) and be lost to the atmosphere relatively quickly after that. The chemical reaction is below, and it occurs through the activity of a soil enzyme called urease. Soils with higher levels of residue contain higher concentrations of urease.

CO(NH2)2 + H2O + urease → 2NH3 +CO2 (urea)

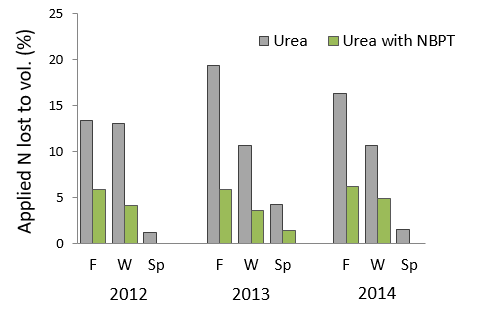

Loss of nitrogen to the atmosphere as ammonia is called volatization and surface applied urea is extremely vulnerable to this process. Montana State University researchers documented losses of up to 44% in trials, with 18% being the average. Losses were highest when the urea was broadcast onto moist soils, with little to no rain for 2 to 3 weeks. In these trials they evaluated NBPT which is a urease inhibitor and observed a reduction in N loss of about 50% (Figure 1 below).

Figure 1. Nitrogen loss from urea broadcast in fall (F) and winter (W) and Spring (Sp). Adding NBPT to urea reduced the loss (R. Engel, MSU).

NBPT is contained in the two nitrogen stabilizer products that we offer, EXCELIS MAXX (Williston) and ANVOL (Fairview and Zahl). ANVOL contains another ingredient, duramide, which can further reduce N loss via volatization.

In addition to the NBPT, EXCELIS MAXX, contains a nitrification inhibitor (DCD) which prevents nitrogen loss via denitrification and leaching. This occurs with the ammonia (NH4+) is converted to nitrate (NO3-) and either lost from the soil via leaching or converted to N2 gas (denitrification).

While it might seem like an unnecessary additional expense, the efficacy of these products in reducing N loss and increasing yield when urea is surface applied has been well documented and it makes sense to protect your fertilizer investment. More information on these ingredients and how they prevent N loss can be found in the NDSU publication “Nitrogen Extenders and Additives.”

Levesol is a product we use in conjunction with our S10 starter fertilizer. It is chelating agent designed to make phosphorous, zinc and other micronutrients (Fe, Cu, Mn) more soluble and thus more available to the plant. Phosphorus has a huge impact on yield potential but unlike nitrogen, it has very limited soil mobility and it gets consistently tied up in the soil, becoming unavailable for plant uptake. The vast majority of phosphorus we apply may not be available for the plant. In fact, it takes almost 10 lbs. of applied phosphorus to increase the soil test phosphorus by one pound and the lower the soil test, the more likely applied phosphorus will be tied up.

Levesol effectively protects the positively charged micronutrients from bonding with the negatively charged soil components and keeps them and the phosphorus soluble for plant uptake. Phosphorus is notorious for binding with positively charged ions in the soil which reduces its availability. Levesol increases the availability of phosphorus by up to 47% with its three modes of action; it unlocks the nutrients in the soil, it makes the nutrients that it’s applied with more available, and it is mobile in the plant for season long activity.

While its not the primary purpose of this product, a nice side benefit is that it cuts down on the dust when handling S10.

GROW Internship Program—Applications Due April 1

Horizon Resources has launched a paid internship program for High School seniors or college students seeking a career in agronomy. Entitled GROW (Guided Real-World Opportunities in Work), this program is designed for students who want to gain practical experience and will help them launch their career after graduation. We are currently accepting applications for our Fairview and Zahl locations and students can submit their application through our website. To learn more, listen to the On The Horizon podcast episode where Williston Location Manager, Austin Semenko, and Dr. Audrey Kalil discuss the program and how to apply.